_________________________________________________________________________________

THE LIBERTY RANGE

The

Liberty is available in three basic versions: the cruiser/racer 47 CR,

the racer/cruiser 45 RC and the racer 45 R.

Both the Liberty 47 CR and 45 RC are semi custom-built and we would

invite clients to make full use of this in joint consultation with the

builder and designer.

The

word 'cruiser' must be stressed, for it means that sea-worthiness and

safety are of primary importance and the construction of the Liberty

is therefore very stiff and strong. This in turn means good manoeuvrability

and a need for fewer 'strong arm' members in the crew.

It also means that she is easy on the helm, even at high speed and thus,

surfing with the Liberty is both fascinating and safe.

A top speed of some 20 knots is quite possible and over longer distances,

average speeds of more than 10 knots have been recorded, even with a

small crew. The evidence is all there: the Liberty has been designed

and built by people who themselves enjoy ocean sailings both cruising

and racing, and who have a wide range of experience in all kinds of

yachts.

The Liberty is a genuine Dutch product of genuine Dutch quality, designed

for sailors who not only wish to sail from port to port, but who also

wish to enjoy the salting to its full extent.

CANCRINUS

YACHTING is managed by Ernst Cancrinus, an experienced and enthusiastic

cruising and racing sailor and the Liberty was specifically designed

by Jac. de Ridder for him.

Cancrinus Yachting is responsible for the organization at all stages

of building, delivery and after-sales service.

If you are in search of the ultimate sailing experience, then the LIBERTY

is the yacht for you.

LIGHT

WITH GOOD REASON

Without

making concessions to strength and quality, the construction of the

Liberty has made full use of weight- saving techniques. Why?

Because a light, fast yacht extends the reach of a

cruising sailor: higher speed averages make further destinations attainable.

Because a light yacht is easier to manoeuvre: smaller

sails and less steering effort require less energy for the crew. Because

a light ship is a dry ship: it glides over the waves rather than powering

through them.

Because 'lighter' means 'less': 'Less' surface sail

area split into a fractional rig results in ease of handling. 'Less'

weight in the mast means 'less' weight in the keel and so 'less' weight

above deck and below the water, meaning 'less' pitching and rolling.

'Less' engine power is required and so a smaller, lighter engine can

be installed. 'Less' weight in the running and standing rigging and

in the deck fittings.

THE

HULL

Jac.

de Ridder has designed a hull of average beam with flowing forms and

a long waterline. A cruiser must be an all-rounder and so extreme forms

have been avoided. A shallow forefoot prevents yawing at high speed

and as the underwater sections forward of the keel have sufficient volume,

the bow will not dig in, even at high speeds in surf.

Similarly, because of the volume of the underwater sections aft of the

keel, the Liberty will surf comfortably without disturbing the underwater

balance.

Thanks, in part, to the moderate beam and the lying waterline length,

the Liberty shows an excellent upwind performance whilst avoiding exaggerated

weather helm. The keel and large, strong balanced rudder result in excellent

course stability with little required steering power - of particular

importance when sailing under autopilot.

THE

RIG

The

fractional rig is the best compromise between manoeuvrability and performance.

A large mainsail and a relatively small foretriangle with the accent

on the high aspect ratio jib and a relatively low spinnaker make the

Liberty a pleasure to sail, even in strong winds.

In very light weather conditions, a high aspect ratio, light-weather

genoa and a large lightweather, masthead spinnaker can be set and thus

the masthead is provided with diamond spreaders.

The spreaders are swept back and this, coupled with shrouds set aft

of the mast, means that running backstops are unnecessary in normal

circumstances.

The trimming variabilities are at all times logical and easy to apply

- one more reason why the Liberty can be sailed perfectly with a small

crew.

THE ACCOMMODATION

Even

at sea, living and working down below is easy and comfortable. Nothing

is more irritating in a yacht than a bad ergonomic design, no matter

how fantastic the performance.

A great deal of attention has been paid to a practical layout in the

galley and navigation area and much consideration has been given to

the accessibility of the cabins, berths, heads, lockers and engine room.

The Liberty is not equipped as a wassailer with berths that can only

be used in port. The off-watch crew can sleep comfortably, irrespective

of the yacht's heeling angle.

Thought has also been given to the long-distance sailor and there is

ample privacy and stowage space to make even the lengthiest of trips

an enjoyable experience.

THE CONSTRUCTION

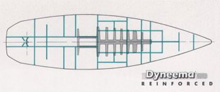

The

joining of hull and interior mouldings results in a single unit: longitudinal

and transverse bulkheads are integrally laminated to the hull, resulting

in a very strong and stiff construction. A fabric containing Dyneema

Superfibre is included within the laminate. Dyneema, even stronger than

Aramide, considerably increases the hull's impact resistance.

The hull layup consists of:

- An outer layer of several layers of isophtal acid gelcoat and hand

laid layers of glass fibre and woven rovings impregnated with resin.

Combined with the paint system below the waterline, this method of construction

renders the chances of osmosis almost nil.

- A Divinicell high density closed cell foam core, through which no

water can penetrate, providing extra stiffness and good sound and temperature

insulation.

- An inner layer of several layers of hand laid glass fibre and woven

rovings and a layer of' Dyneema Superfibre impregnated with resin.

- At the keel, rudder and engine mountings, the hull is amply reinforced

with extra layers of uni-directional glassfibre.

- Like the hull, the deck is sandwich built and reinforced with extra

layers of glass fibre beneath all fittings such as: winches, chain plates,

toe rail, stoppers etc.

Both hull and deck are constructed to drawings approved by German Lloyds,

in climate controlled sheds which also comply with German Lloyds standards;

a perfect laminate is guaranteed.

FITTING OUT

Just

as the hull, deck, longitudinal and transverse bulkheads are laminated

into a very stiff and strong unit by specialised workers, so the Liberty

is fitted out by a team of highly regarded craftsmen.

A heavy interior would undoubtedly spoil the character of the Liberty

and so the builders have opted for an attractive but functional finish

without superfluous luxury that can only lead to increased weight.

There is a choice of traditional or lnodern interiors with no difference

in weight.

The type of wood trim, upholstery, lighting etc is chosen by the owner

and thus, with many possible variations, each Liberty has an individual

appeal.

THE EQUIPMENT

All

items of equipment, from mast to engine, from running rigging to cabin

lights, are from well-known manufacturers such as Proctor, Volvo, Lewmar,

Harken, Marlow, etc.

As standard, the sails are of a very high quality and, if specified,

can be fabricated in Mylar, Dyneema or Kcvlar. All electric cables are

installed via easily accessible conduits, through which additional cables

can be drawn if required at a later date. To give the electrical circuits

optimum protection against moisture, all connections are soldered and

varnished.